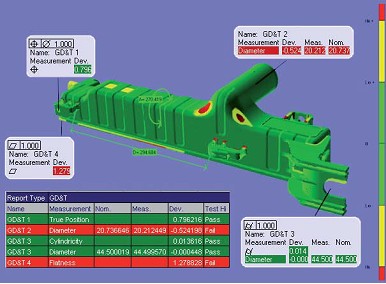

ShapeGrabber systems are the ideal tool for rapid inspection of complex shaped parts such as plastic injection molded components. Unlike traditional methods that rely on the inspection of a few points, the non-contact ShapeGrabber technology captures millions of accurate data-points that represent the true geometry of the complete part which is then compared directly to CAD. The result is that production staff can make rapid pass/fail decisions with confidence and designers get accurate and timely feedback on prototypes.

|

|

Features

? Full 3D Quality Control ? Auto inspection in minutes ? Easy to use, no programming ? No CAD training required ? Go/No Go: back to production ? Complete design verification ? Save and print reports ? Save and share data |

|

ShapeGrabber will make short work of measuring: ? Full surface inspection (shape) ? Bow and warpage ? Shrinkage and wall thickness ? Cross-sections ? Holes (size, center to center, true position) ? Angles ? Diameters & Radii ? Flush & Gap ? And more… |

|